Cotton is a ubiquitous material used for everything from clothing to upholstery due to its comfort, softness, and breathability. However, one significant downside of cotton is its flammability, which poses a potential risk to life and property. Despite its widespread use, cotton, like many natural fibers, is highly susceptible to catching fire. In light of this, researchers at Texas A&M University have pioneered a groundbreaking approach to significantly reduce cotton’s flammability by utilizing a polyelectrolyte complex coating. This innovative method, which can be applied to a variety of textiles, such as clothing and upholstery, promises to offer enhanced fire protection and could dramatically improve safety in everyday life.

The breakthrough, developed by a team of researchers in the Department of Chemistry at Texas A&M, led by graduate student Maya D. Montemayor, provides a simple, cost-effective, and scalable solution to an age-old problem. “Many of the materials in our day-to-day lives are flammable, and offering a solution to protect from fire benignly is difficult,” Montemayor explained. “This technology can be optimized to quickly, easily, and safely flame retard many flammable materials, offering vast protection in everyday life, saving money and lives of the general population.”

Historically, the development of flame-retardant coatings for textiles has involved multiple, time-consuming, and costly steps. Coating processes typically require the application of several layers of chemicals to achieve a reduction in flammability. These treatments are often complex and resource-intensive, increasing both the cost and time associated with the production of flame-retardant textiles. However, the Texas A&M research team has demonstrated that it is possible to achieve a high level of flame retardancy in a single, efficient step, drastically reducing the processing time and costs.

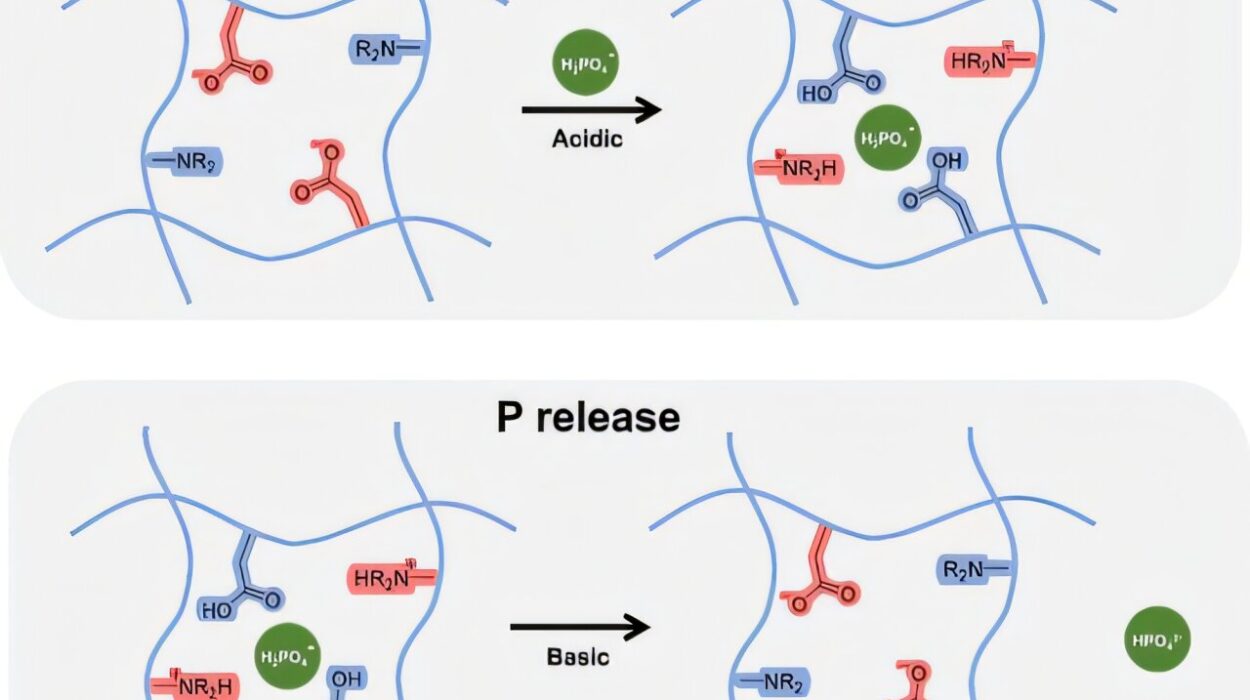

The team’s approach, which was recently published in ACS Applied Polymer Materials, involves the application of a polyelectrolyte complex that only requires one step for effective treatment. The breakthrough process uses ammonia as the volatile base. The ammonia evaporates at ambient conditions, lowering the pH and inducing a chemical reaction that creates a stable complex on the surface of the cotton fibers. This results in a coating that enhances the cotton’s resistance to fire.

Until now, this approach had been theorized but never successfully applied in flame-retardant treatments. The key innovation of this method lies in its simplicity and speed. Whereas traditional flame retardant treatments often rely on intricate multi-step processes, this one-step technique reduces complexity while still achieving the desired outcomes. This innovation could revolutionize the textile industry, particularly for products that demand both comfort and safety.

In addition to being faster and more cost-effective, the new coating method is aqueous and non-toxic. Most traditional flame-retardant treatments rely on chemicals that can be harmful to both the environment and human health. Many existing flame retardant coatings are made with substances that are either toxic to the user or toxic to the environment when the textile is disposed of. This new technology, on the other hand, offers a safer and more environmentally friendly alternative. The use of water-based solutions ensures the process is less harmful than other chemical alternatives, which often release hazardous compounds into the atmosphere.

The potential applications for this breakthrough technology extend far beyond cotton fabrics. Researchers have explored the possibility of adapting this technology to other materials, such as wood, foam, and synthetic textiles. As textiles are used in a variety of high-risk applications—from upholstered furniture and home textiles to car interiors and hospital linens—having a flame-retardant option that can be easily applied and scaled for industrial use could drastically improve safety standards across multiple industries.

The research team is now in the process of collaborating with companies to further evaluate and refine the technology for commercial use. Potential partnerships will focus on making the technology available for industrial applications, potentially transforming the manufacturing of fire-resistant materials. By providing a cost-effective solution that could be scaled up, this research has the capacity to save lives and reduce property damage, especially in environments where fire risks are prevalent.

Looking ahead, the team of researchers, including graduate students Danixa Rodriguez-Melendez, Dallin L. Smith, Natalie A. Vest, and Bethany Palen, as well as undergraduate students Edward Chang and Alexandra V. Moran, aim to explore other ways to optimize the technology for broader use. As fire safety remains a priority for many industries, the development of a flame retardant coating that is both easy to apply and effective in reducing the flammability of everyday materials holds tremendous promise. By ensuring that textiles—whether used in personal clothing, public spaces, or commercial settings—are better protected against fire hazards, the technology developed by Texas A&M University could play a critical role in creating safer environments for people everywhere.

Reference: Maya D. Montemayor et al, Evaporation Induced Flame Retardant Polyelectrolyte Complex for Cotton, ACS Applied Polymer Materials (2024). DOI: 10.1021/acsapm.4c02937