In the pursuit of sustainability and recycling, modern materials, especially those used in consumer electronics, are under increasing scrutiny. Among these, organic light-emitting diodes (OLEDs) have emerged as one of the most promising technologies for display screens in consumer electronics such as televisions and portable devices. OLEDs are renowned for their high contrast and low power consumption, which have made them the go-to choice for modern display technologies. However, the road to discovering and creating the right materials for OLEDs—especially materials that are both efficient and environmentally friendly—has historically been long, complex, and time-consuming.

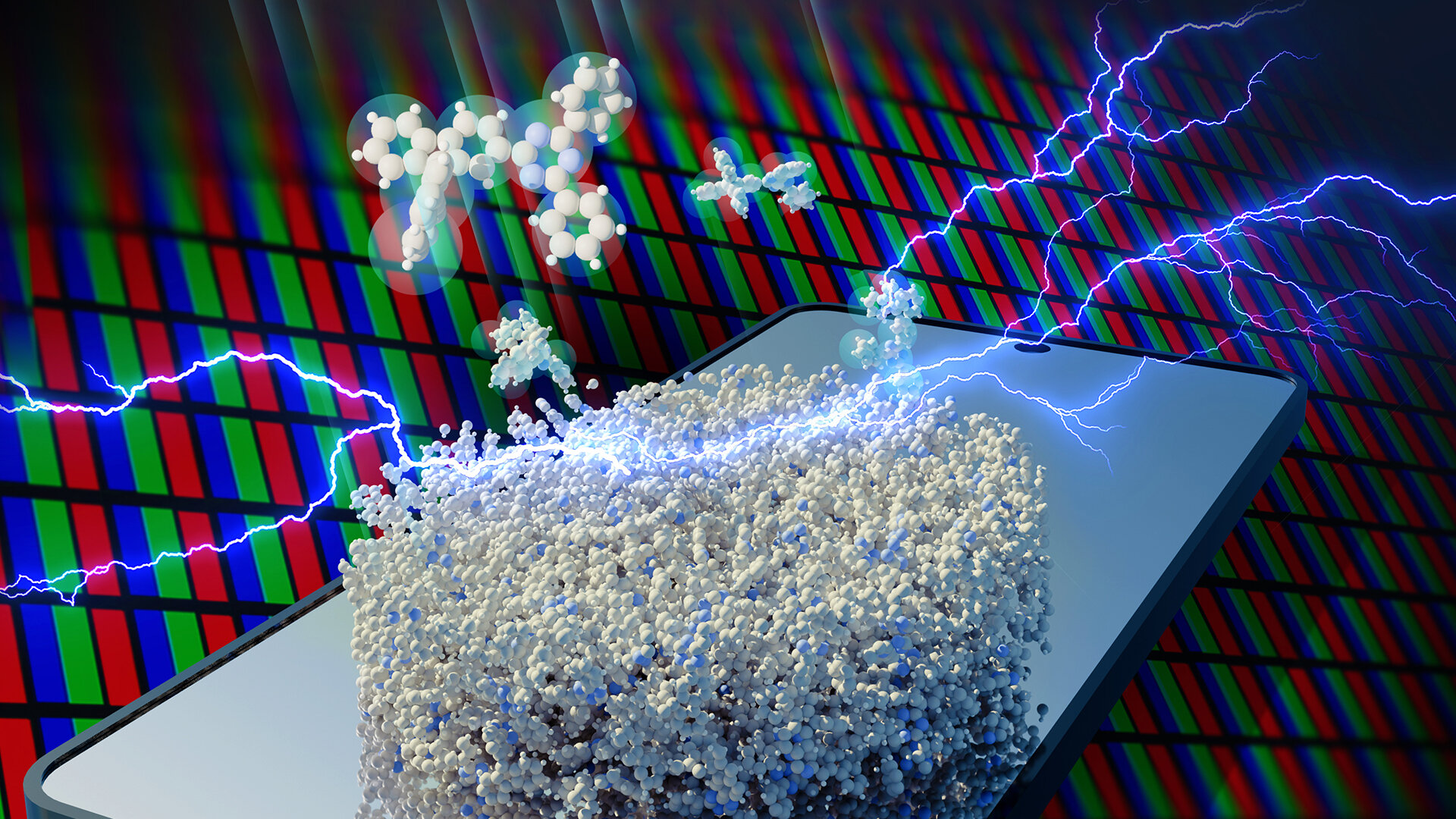

A major hurdle in the development of OLED technology lies in the process of tailoring and optimizing the materials used. OLEDs function by utilizing thin films of organic molecules—carbon-based molecules that emit light when electricity is applied. These molecules are carefully chosen for their electronic properties, but the challenge lies in how these molecules interact with each other when assembled into thin films. As the design of OLED devices progresses, the need for materials that are not only high-performing but also sustainable and recyclable becomes more critical.

Until recently, the creation of OLED materials often relied on a trial-and-error method. Scientists and engineers would synthesize molecules, deposit them into thin layers, and test the resulting material’s performance. This process, especially for complex OLEDs that consist of multiple layers, could take years to refine, as even a minor change in one layer could drastically impact the overall performance. Since each OLED typically consists of several thin layers, each of which may require different materials, finding the optimal combination for the best performance becomes a very intricate and resource-intensive task.

But this approach is no longer the most efficient path forward. To speed up the development process, scientists are increasingly turning to computational simulations. In particular, a group of researchers led by Denis Andrienko from the Max Planck Institute for Polymer Research and Falk May from Display Solutions at Merck have developed a novel simulation method that could significantly accelerate the development of new OLED materials. Their work, published in the journal Advanced Energy Materials, offers a potential breakthrough in the way organic materials are studied and optimized for use in electronics.

The key features of an OLED—high contrast and low power consumption—are achieved by the organic molecules themselves, but how these molecules are arranged in the thin films that make up the OLED is of critical importance. The current standard in semiconductor materials—such as silicon—relies on inorganic materials that are well-studied and highly predictable. However, organic materials, while offering the potential for higher flexibility, lower cost, and better environmental sustainability, present unique challenges. One of the greatest challenges is predicting how these materials will behave once they are arranged in the thin films necessary for OLED displays.

Traditional computational methods, such as quantum chemical calculations, can help predict the properties of individual molecules, but they struggle to model the behavior of large assemblies of molecules. This is particularly true when dealing with thin films, where the molecular packing and arrangement depend heavily on processing conditions—such as how fast molecules are deposited onto a surface. The deposition rate, for instance, can affect how molecules align with each other, how smooth the surface is, and what the refractive index of the film will be. These factors play a crucial role in the performance of the OLED, but simulating them in detail on an atomic scale is computationally expensive and often unfeasible, even with today’s advanced computing power.

To address this issue, Andrienko and May’s team developed a method called “coarse-graining,” which simplifies the representation of molecules in the simulations. Instead of describing every individual atom of the molecules, coarse-graining involves grouping atoms together to create a simplified model of the molecule. This approach drastically reduces the computational complexity and allows simulations to span longer periods, from seconds to even hours, which is typical for the deposition process. By skipping some of the more granular atomic details, the team is able to simulate the behavior of molecules in the context of film deposition, making predictions about how molecules will pack together in thin layers.

This coarse-graining approach offers several advantages. First, it significantly speeds up the simulation process, allowing scientists to test more potential materials and processing conditions in a fraction of the time it would take with traditional methods. The faster simulation times make it possible to explore a broader range of material combinations, which can lead to the discovery of new, more efficient OLED materials. Additionally, the simulation can also provide insights into how changes in processing conditions—such as deposition rate or temperature—might affect the film’s performance.

By offering a faster and more efficient way to predict the behavior of organic molecules in OLED materials, this new approach opens the door to more rapid advancements in the field of organic electronics. In practical terms, this could mean that OLED technology becomes more accessible, affordable, and environmentally sustainable. The ability to simulate the deposition process and material behavior also helps avoid the costly trial-and-error process of physical experimentation, which can take months or even years.

One of the most promising aspects of this new simulation method is its potential to make OLED technology more sustainable. As the demand for energy-efficient and recyclable consumer electronics grows, organic electronics are poised to play a significant role. OLEDs, in particular, offer the promise of lower power consumption, longer lifespan, and the possibility of using more environmentally friendly materials. By accelerating the development of high-performing OLED materials through advanced simulations, researchers can push the boundaries of what is possible in terms of performance and sustainability.

Moreover, this new simulation approach could have far-reaching implications beyond OLED technology. The principles of coarse-graining and molecular modeling could be applied to a wide range of other organic electronics, including organic solar cells, organic semiconductors, and even organic transistors. The ability to predict material properties and behaviors before physically synthesizing the materials could revolutionize not only the consumer electronics industry but also other fields such as renewable energy and materials science.

Reference: Christoph Scherer et al, Predicting Molecular Ordering in Deposited Molecular Films, Advanced Energy Materials (2024). DOI: 10.1002/aenm.202403124