The aviation industry, with its nearly total reliance on fossil fuels, faces a significant hurdle in its ongoing efforts to reduce carbon emissions and transition to more sustainable sources of energy. While there has been growing interest in developing sustainable aviation fuels (SAFs) made from waste fats, oils, plant biomass, and other non-petroleum resources, a critical challenge has persisted: these fuels often lack sufficient aromatic hydrocarbons. These essential hydrocarbons play a key role in fuel performance by lubricating mechanical systems and preventing leaks, both of which are crucial for ensuring the safety and efficiency of aircraft.

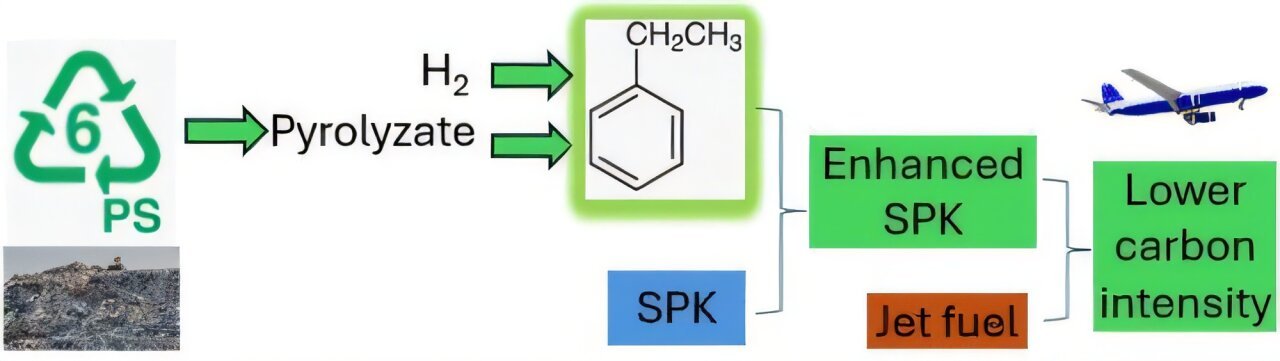

A new study published in ACS Sustainable Chemistry & Engineering offers a promising solution to this issue. The research, led by Hong Lu, a scientist from the Illinois Sustainable Technology Center (ISTC), part of the Prairie Research Institute at the University of Illinois Urbana-Champaign, presents a method for producing ethylbenzene—an important aromatic hydrocarbon—by using polystyrene, a hard plastic that is frequently used in consumer goods. The study not only overcomes a key technical challenge but also offers a more sustainable and cost-effective method to support the aviation sector’s gradual switch to greener energy.

The Problem with Aromatic Hydrocarbons

Sustainable aviation fuels (SAFs) offer a potential solution to the climate crisis by providing cleaner, less carbon-intensive alternatives to conventional jet fuel. However, for SAFs to be viable alternatives on a large scale, they must meet specific performance standards. One of the essential requirements for SAFs is that they include at least 8.4% aromatic hydrocarbons in their blend with traditional fossil-based jet fuel. This standard is necessary to ensure the fuel’s compatibility with existing aircraft and their systems. Aromatic hydrocarbons serve vital functions in aircraft fuel systems, including lubricating pumps and seals that keep mechanical parts functioning smoothly during flight, as well as minimizing fuel degradation during storage.

However, fuels derived from waste fats, oils, and plant materials typically contain only 0.5% aromatic hydrocarbons. This shortfall limits the proportion of sustainable aviation fuels that can be used in jet engines, as current safety standards demand a higher concentration. As a result, SAFs are blended with conventional jet fuel—often making up only 20% to 30% of the fuel mix. This situation has created a bottleneck in the adoption of SAFs, despite their environmental benefits.

The Role of Ethylbenzene

Ethylbenzene, a type of aromatic hydrocarbon, has the required qualities for aviation fuel: it helps lubricate critical systems and maintain fuel integrity. While ethylbenzene can be derived from fossil fuels, this process is carbon-intensive and detracts from the overall sustainability of the final fuel product. In light of this, finding an eco-friendly and cost-effective method to produce ethylbenzene has become a key priority for researchers aiming to accelerate the adoption of sustainable aviation fuels.

One of the biggest hurdles in replacing fossil-based ethylbenzene with a sustainable alternative lies in sourcing the right material. Fortunately, polystyrene—a ubiquitous plastic used in everything from packaging to disposable cutlery—has proven to be a highly promising candidate. Polystyrene is carbon-rich and abundant, with an estimated 2.5 million metric tons produced each year in the U.S. Unfortunately, much of it ends up in landfills, contributing to environmental pollution. However, by using this readily available plastic waste, Lu and his team were able to develop a method of producing ethylbenzene in a way that both reduces waste and advances the creation of sustainable aviation fuels.

Transforming Polystyrene into Ethylbenzene

To produce ethylbenzene from polystyrene, Lu and his colleagues employed a two-step process: thermal pyrolysis and hydrogenation. In the first step, polystyrene is subjected to thermal pyrolysis—a method that involves heating the plastic to high temperatures in the absence of oxygen, breaking it down into smaller, more reactive molecules. The resulting product is a styrene-rich liquid, which is a critical precursor for further chemical transformation.

The second step involves hydrogenation—a process that adds hydrogen atoms to the styrene, converting it into a crude form of ethylbenzene. The team then purified this product through distillation, resulting in an ethylbenzene that was 90% pure. This method proved highly successful in generating a usable product that met the industry standards required for blending with SAFs.

Promising Results for Aviation Fuels

When the team tested their polystyrene-derived ethylbenzene in a blend with sustainable aviation fuel, the results were encouraging. The ethylbenzene derived from waste polystyrene performed nearly as well as conventional ethylbenzene from fossil fuels, with almost identical lubricating and sealing qualities. Furthermore, the cost of producing ethylbenzene from waste polystyrene is lower than that of traditional methods that rely on crude oil. This translates to a potential reduction in overall fuel costs as well as a decrease in reliance on fossil fuels.

Moreover, a lifecycle analysis revealed that the production of ethylbenzene from polystyrene-derived feedstocks can lead to a 50% to 60% reduction in carbon emissions compared with conventional fossil-based ethylbenzene production. This reduction is a critical advantage in the ongoing efforts to reduce aviation’s carbon footprint and meet ambitious sustainability goals set by governmental agencies.

A Path to Greater Use of Sustainable Aviation Fuels

Lu’s breakthrough has significant implications for the aviation industry’s push toward a more sustainable future. Sustainable aviation fuels are considered a major component of strategies to reduce aviation’s carbon emissions, which currently account for a sizable portion of global greenhouse gas emissions. To meet the demands of climate change mitigation, the U.S. Department of Energy, the U.S. Department of Transportation, the U.S. Department of Agriculture, and several other agencies have outlined ambitious targets for SAF production. These goals include producing 3 billion gallons of SAFs per year by 2030 and scaling up to 100% of projected U.S. aviation fuel consumption—35 billion gallons per year—by 2050.

However, achieving these targets has been challenging. Although alternative fuel sources like plant-based biomass and waste oils offer a sustainable solution, overcoming the technical challenges surrounding aromatic hydrocarbon levels remains a major obstacle. By utilizing waste polystyrene to produce the necessary aromatic hydrocarbons—specifically ethylbenzene—Lu’s study provides a potential pathway to significantly increase the share of SAFs in the aviation industry’s fuel supply.

Potential for Future Innovation

Lu and his colleagues intend to continue refining their method of producing ethylbenzene from waste polystyrene. The next steps include improving the efficiency of the purification process and further optimizing the hydrogenation step to achieve a product that is closer to 100% pure. They also plan to investigate the impact of the polystyrene-derived ethylbenzene in larger fuel blends to ensure its continued compatibility with aircraft systems.

In addition, the successful use of polystyrene in producing sustainable aviation fuel additives could spur the development of other similar initiatives targeting commonly discarded plastics. By finding practical ways to repurpose widely produced plastic waste, researchers could help reduce plastic pollution and support the broader transition toward a more sustainable, circular economy.

Conclusion

The production of ethylbenzene from waste polystyrene is a significant step forward in the aviation industry’s shift toward sustainable fuels. By turning a plastic waste product into a valuable and essential component of aviation fuel, this innovation holds the promise of not only reducing the environmental impact of aviation but also cutting the cost of sustainable fuel production. Furthermore, it provides a concrete example of how addressing environmental waste can offer solutions to pressing challenges, moving the industry closer to achieving climate and sustainability goals. As research in this area continues to advance, the adoption of sustainable aviation fuels and a greener, more efficient future for the aviation industry become ever more attainable.

Reference: Ravindra Prajapati et al, Production of a Sustainable Aviation Fuel Additive from Waste Polystyrene, ACS Sustainable Chemistry & Engineering (2024). DOI: 10.1021/acssuschemeng.4c06748

Think this is important? Spread the knowledge! Share now.