The rise of technology has ushered in a new era of innovation and transformation, especially in the realm of digital modeling. Among the most exciting and revolutionary developments in recent years is the concept of Digital Twins. These virtual replicas of physical entities are transforming industries by allowing businesses to simulate, analyze, and optimize their real-world counterparts in real-time. From manufacturing and healthcare to urban planning and disaster management, digital twins are pushing the boundaries of what is possible, unlocking new levels of efficiency, sustainability, and innovation.

In this extensive exploration of digital twins, we’ll delve into how this groundbreaking technology works, its numerous applications, the challenges and opportunities it presents, and the profound impact it’s having on our world today and in the future. Whether you’re a tech enthusiast, a business leader, or just curious about emerging technologies, this deep dive into the realm of digital twins will provide you with a comprehensive understanding of their power and potential.

What is a Digital Twin?

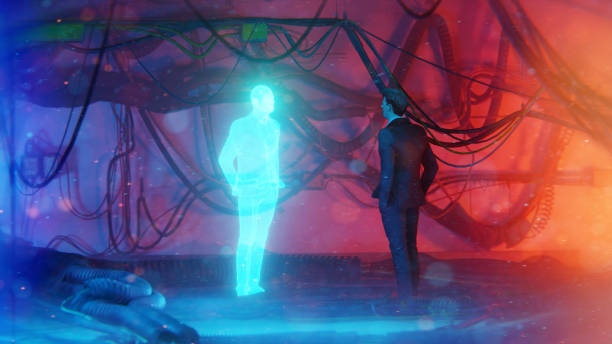

A Digital Twin is essentially a virtual representation of a physical object, system, or process. It mirrors the real-world counterpart, providing a dynamic and continuous stream of data, often in real-time. Imagine a highly detailed and interactive digital version of a factory, a car engine, a building, or even a person’s health. The digital twin mimics the real-world behavior of its physical counterpart and can be used to track performance, predict issues, or simulate changes before they happen in the physical world.

The digital twin is not just a static model; it’s an evolving, data-driven reflection of the real-world entity. Using sensors, IoT (Internet of Things) devices, and advanced analytics, digital twins can be continuously updated, allowing for constant monitoring and management. This live feedback loop between the physical and virtual worlds makes digital twins incredibly powerful for improving operational efficiency, reducing costs, enhancing decision-making, and enabling new forms of innovation.

The Evolution of Digital Twins: From Concept to Reality

The idea of digital twins was first conceptualized by Dr. Michael Grieves in 2002 during a presentation at the University of Michigan. He introduced the concept as part of his work on Product Lifecycle Management (PLM), where he proposed that each product could have a digital counterpart to track its lifecycle from design to manufacturing and beyond.

However, it wasn’t until the growth of IoT and advancements in data analytics and cloud computing in the 2010s that the concept began to take shape in a practical sense. The combination of cheap sensors, ubiquitous internet connectivity, and powerful computing infrastructure allowed companies to start building real-time, interactive digital twins.

Today, digital twins are used across various industries, with new applications emerging regularly. The rise of big data, machine learning, and artificial intelligence has further accelerated the adoption and evolution of digital twins, pushing them beyond just modeling and simulation tools into critical instruments for business optimization and innovation.

The Core Technologies Behind Digital Twins

Digital twins rely on several interconnected technologies to operate effectively. At the heart of every digital twin is data—lots of it. The virtual models require continuous updates to remain accurate, and this data often comes from various sources, including sensors, machines, human inputs, and environmental data.

Here are the key technologies that enable digital twins to function:

- Internet of Things (IoT): IoT devices, which include sensors, actuators, and other connected equipment, play a central role in the development of digital twins. These devices collect real-time data from the physical object or system, which is then fed into the digital twin model. For instance, in a manufacturing plant, sensors on machines might monitor temperature, vibration, and other parameters that are then reflected in the digital twin.

- Cloud Computing: Cloud computing provides the scalability and computational power needed to handle the massive amounts of data that digital twins generate. With cloud-based infrastructure, digital twins can be stored, accessed, and processed in real-time, even from remote locations. This makes it possible for businesses to manage and optimize their physical assets without being tied to a specific location.

- Big Data Analytics: The vast amounts of data generated by IoT sensors and other sources are processed and analyzed using big data analytics. This allows businesses to identify patterns, trends, and anomalies in their digital twin models. With the right analytics tools, digital twins can become predictive, offering insights into potential failures or areas for improvement before they manifest in the physical world.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms help digital twins make sense of the data they collect, and even predict future outcomes. For example, machine learning models can analyze historical data to forecast when a machine might need maintenance or identify inefficiencies in a process. AI can also optimize system performance based on real-time feedback from the digital twin.

- Simulation and Modeling: To create a digital twin, businesses must first build an accurate virtual model of the physical entity. This requires sophisticated modeling and simulation tools. These tools enable companies to create high-fidelity replicas that capture the exact behavior of physical objects or systems. By running simulations on the digital twin, businesses can test different scenarios, troubleshoot issues, and explore new design ideas without any risk to the physical system.

- Edge Computing: As IoT devices proliferate and generate real-time data, processing this data in the cloud can sometimes introduce latency issues. Edge computing solves this problem by processing data closer to where it’s generated. By performing real-time analytics and decision-making at the edge of the network, digital twins can operate more quickly and efficiently.

Applications of Digital Twins

The potential applications of digital twins are vast and growing. Below, we explore some of the most significant industries and sectors where digital twins are making a profound impact.

1. Manufacturing

Manufacturing is one of the most prominent areas where digital twins are making waves. By creating virtual replicas of production lines, machines, and products, manufacturers can optimize their processes, predict maintenance needs, and improve product quality. Digital twins in manufacturing allow for real-time monitoring, enabling early detection of inefficiencies or potential failures. They can also facilitate predictive maintenance, reducing downtime and costly repairs.

One key example is General Electric (GE), which uses digital twins to monitor and optimize the performance of its jet engines. By creating digital models of each engine, GE can track data such as temperature, pressure, and vibrations to predict when maintenance is required, improving reliability and reducing operational costs.

2. Healthcare

In healthcare, digital twins are being used to create personalized models of patients, allowing for more accurate diagnosis, treatment planning, and monitoring. By combining patient data with digital twin models of organs or bodily systems, doctors can simulate how different treatments might affect the body, leading to more precise and tailored care.

For instance, Philips is using digital twins to model the human heart, allowing for better cardiovascular care. By simulating the effects of various drugs or surgical interventions on the heart’s functioning, healthcare providers can make more informed decisions, improving outcomes and reducing the risk of complications.

3. Smart Cities and Urban Planning

Urban planners are using digital twins to design smarter, more sustainable cities. By creating digital replicas of entire cities or urban areas, planners can model traffic flows, energy consumption, water distribution, and other critical systems. This allows for better decision-making when it comes to infrastructure development, resource management, and disaster response.

For example, Singapore has created a digital twin of the entire city, known as the Virtual Singapore project. This model integrates data from sensors across the city, allowing authorities to monitor traffic, pollution, weather patterns, and energy usage in real-time. The city’s planners can then use this data to make more informed decisions about urban development, environmental conservation, and disaster preparedness.

4. Energy and Utilities

The energy sector is another area where digital twins are making a significant impact. Power plants, oil rigs, and renewable energy sources can all be modeled digitally to improve efficiency, safety, and sustainability. Digital twins can help operators monitor the condition of equipment, predict maintenance needs, and optimize energy production.

In wind energy, for instance, companies like Siemens Gamesa are using digital twins to optimize the performance of wind turbines. By analyzing real-time data from the turbines, digital twins can identify issues such as blade wear or vibration, enabling operators to perform maintenance before costly failures occur.

5. Aerospace and Automotive

In the aerospace and automotive industries, digital twins are used to design, test, and optimize vehicles before they are built. Aircraft manufacturers like Boeing and automotive companies like Ford use digital twins to simulate vehicle performance under various conditions, reducing the need for expensive and time-consuming physical prototypes.

In aerospace, digital twins can also be used for real-time monitoring of aircraft systems during flight. This allows maintenance teams to predict when parts will need replacement or repair, increasing the safety and efficiency of airline operations.

The Challenges of Digital Twins

While the potential of digital twins is vast, there are several challenges that need to be addressed before the technology can reach its full potential. Some of these challenges include:

- Data Security and Privacy: The real-time data generated by IoT sensors and other devices is crucial for the functioning of digital twins, but it also raises significant concerns around data security and privacy. Protecting this data from cyberattacks and ensuring it is used responsibly is a top priority for businesses deploying digital twins.

- Integration with Legacy Systems: Many organizations are working with legacy systems that may not be compatible with the latest digital twin technologies. Integrating these systems with newer platforms can be complex and costly, requiring significant investments in infrastructure and software.

- Data Management: The sheer volume of data generated by digital twins can be overwhelming. Organizations must ensure they have the proper infrastructure and data management strategies in place to handle, store, and analyze this data efficiently.

- Cost: Building and maintaining digital twins can be expensive. The cost of sensors, software, and infrastructure required to create and update digital twins can be a barrier to entry for some organizations, especially small and medium-sized businesses.

The Future of Digital Twins

As technology continues to evolve, the future of digital twins looks incredibly promising. With advancements in AI, 5G connectivity, and edge computing, digital twins are set to become even more sophisticated and widely adopted across industries. The integration of augmented reality (AR) and virtual reality (VR) technologies will also make interacting with digital twins more immersive and accessible.

In the coming years, we can expect to see digital twins become even more integrated into everyday life, helping businesses and governments make smarter decisions, improve efficiency, and drive innovation. The possibilities are endless, and the digital twin revolution is only just beginning.

In conclusion, digital twins are not just a futuristic concept—they are a present-day reality that is reshaping industries, optimizing operations, and providing valuable insights that were once unimaginable. By creating virtual models of the real world, digital twins are offering organizations the ability to simulate, predict, and optimize like never before. As technology continues to advance, we can only expect these virtual replicas to become more powerful, more integrated, and more influential in the years ahead. The impact of digital twins on the world will continue to grow, and the future of this technology promises to be as exciting as it is transformative.