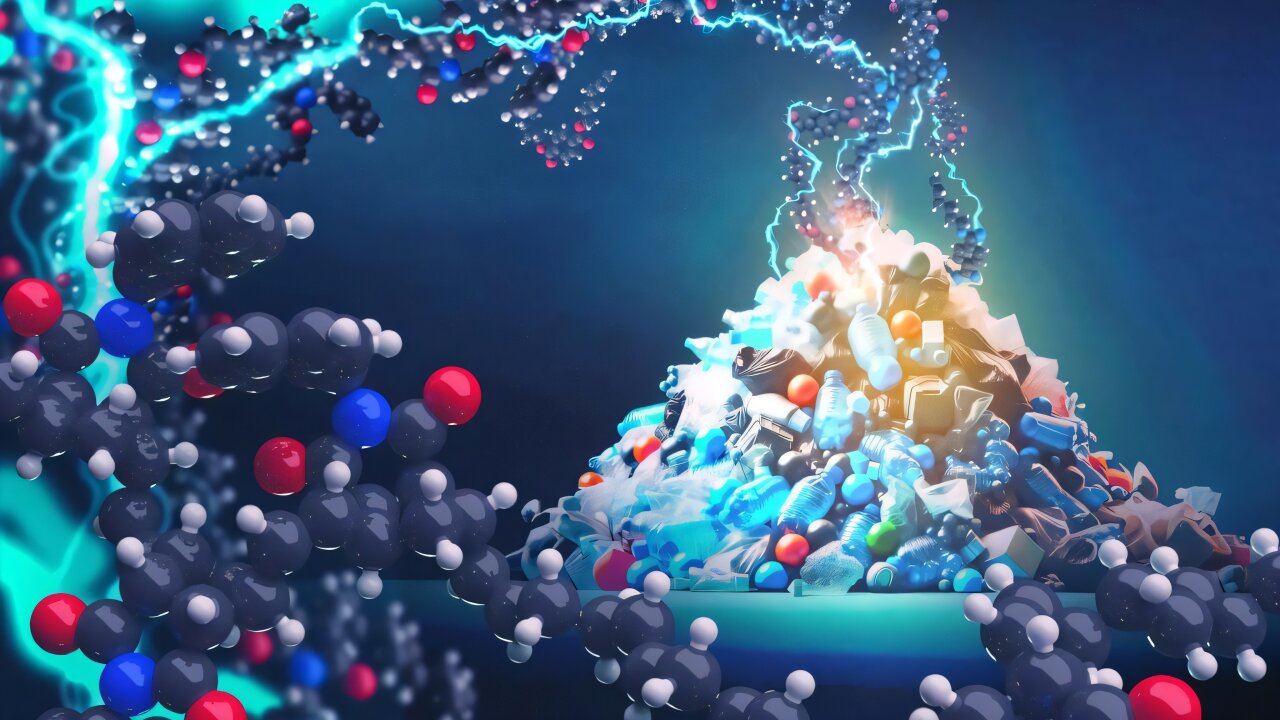

The problem of plastic waste is one of the most pressing environmental issues facing the world today. Every year, approximately 450 million tons of plastic are discarded globally, with a staggering 91% of it not being recycled. Instead, it ends up in landfills, oceans, or incinerated, contributing to environmental degradation. But in a significant breakthrough, chemists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have developed a method to upcycle discarded plastics into valuable new materials by editing their polymer chains. This could revolutionize the way plastics are recycled and lead to a more sustainable future.

What is Upcycling Plastic?

Traditional plastic recycling typically involves melting down plastics, which often results in the degradation of their material properties after repeated cycles. This process makes it difficult to extract any additional value from the recycled material. However, the ORNL’s innovative upcycling technique goes beyond simple recycling by using molecular editing to rearrange and customize the properties of plastic polymers.

Instead of merely reusing the polymers in their degraded form, the ORNL team has discovered a way to generate new macromolecules with more desirable properties than those of the original plastic. The process essentially gives new life to waste plastics by rearranging their building blocks at the molecular level, creating more durable, functional, and versatile materials that can be repurposed for a variety of applications.

This upcycling method focuses on polymeric materials—the long chains of molecules that form the backbone of most plastics. By selectively breaking and forming new chemical bonds, the researchers can change the material properties of these polymers, making them stronger, more rigid, or more heat-resistant, depending on the desired outcome.

The Science Behind the Innovation

The breakthrough relies on molecular editing, a powerful tool that has been pivotal in other fields of science. In fact, molecular editing has been the foundation of two Nobel Prizes in Chemistry. In 2005, the Nobel Prize was awarded for the development of metathesis, a process that enables the breaking and making of double bonds between carbon atoms in polymers. In 2020, the prize was awarded for CRISPR technology, which allows for precise modifications to DNA strands.

ORNL’s approach to upcycling plastic waste mirrors these groundbreaking technologies but applies them to polymeric chains rather than genetic material. As Jeffrey Foster, the lead scientist behind the study, explained, “This is CRISPR for editing polymers. However, instead of editing strands of genes, we are editing polymer chains.”

The researchers’ primary goal is to address a significant portion of plastic waste, which often includes commodity polymers such as polybutadiene and acrylonitrile butadiene styrene (ABS). These materials are widespread in products like rubber tires, plastic toys, ventilation pipes, vehicle trim, protective headgear, and even kitchen appliances. Unfortunately, these plastics are rarely recycled effectively due to their complexity and lack of reusability.

The ORNL team’s method starts by dissolving these waste polymers in a solvent, like dichloromethane, at relatively low temperatures. This dissolution process is followed by a chemical reaction facilitated by a ruthenium catalyst, which promotes polymerization—essentially building new polymer chains by linking functional units. This process is very similar to how industrial firms use catalysts to produce robust plastics or convert biomass into fuels. The key advantage of this upcycling process is that it enables the creation of high-value organic compounds and multipurpose plastics from what would otherwise be waste materials.

The Key Techniques: Metathesis and Polymerization

The ORNL scientists employed two forms of metathesis—the rearrangement of chemical bonds—during the upcycling process. The first is called ring-opening metathesis polymerization (ROMP), which opens carbon rings and elongates them into polymer chains. The second, known as cross metathesis, allows for the exchange of polymer subunits between different chains, effectively merging two distinct polymers into a single, more functional material.

These techniques take advantage of double bonds in the polymer chains, which act as reactive sites for polymerization. The double bonds allow the molecules to “swap” functional groups, enabling the creation of new polymer chains with enhanced properties. By carefully controlling the molecular weight of the resulting polymers, scientists can dictate their performance and tailor the materials to suit specific applications.

This is a far cry from traditional recycling methods, which typically involve melting plastic and hoping it can be reused without significant loss of quality. In contrast, ORNL’s process preserves the material’s structure and enhances its properties, providing a far more efficient and sustainable way to deal with plastic waste.

Environmental and Economic Impact

The implications of ORNL’s upcycling process are immense. If scaled up, it could dramatically reduce the environmental impact of plastic waste. By converting low-value waste materials into high-value products, the technology offers a potential solution to the global plastic waste crisis. Foster highlighted that the technology could be transformative, stating, “We’re addressing a significant component of the waste stream with this technology. That would make a pretty big impact just from the conservation of mass and energy from materials that are now going into landfills.”

Additionally, this process uses less energy and produces fewer emissions compared to traditional recycling methods. Because it works directly with the existing polymer building blocks, it can generate useful materials with minimal waste. This makes the process economically viable and a greener alternative to current recycling technologies, which often require high temperatures and extensive processing.

By improving the properties of recycled plastics, ORNL’s upcycling could also open up new markets for recycled materials, making the recycling process more economically attractive to industries that currently rely on virgin plastic. The ability to produce high-performance materials from waste could make recycling more profitable and encourage the broader adoption of circular economy principles—where materials are repurposed rather than discarded.

Broadening the Scope of Upcycling

While the current research focuses on common waste plastics like polybutadiene and ABS, the team at ORNL is optimistic about expanding the technology to a wider range of polymers. The goal is to optimize the process for different types of plastics and customize the molecular properties to create materials that are softer, stretchier, or more heat-resistant, depending on the end-use application.

Moreover, the researchers are exploring ways to apply their methods to thermoset plastics, which are notoriously difficult to recycle. Thermosets, such as epoxy resins, vulcanized rubber, polyurethane, and silicone, undergo a curing process that makes them rigid and cross-linked, rendering them unable to be reshaped or remelted. This creates a significant recycling challenge. However, the team at ORNL is experimenting with changing the types of subunits in the polymer chains to produce high-performance thermoset materials that could be easier to recycle in the future.

Another avenue of research involves improving the environmental sustainability of the solvents used in the process. While the current solvent, dichloromethane, is effective, the researchers are looking for ways to replace it with greener alternatives to further reduce the environmental impact of the upcycling process.

Conclusion

The innovative upcycling method developed by ORNL offers a promising solution to the global plastic waste crisis. By harnessing molecular editing techniques, such as metathesis polymerization, ORNL has demonstrated a way to transform discarded plastics into high-value materials with customizable properties, moving beyond traditional recycling methods that often degrade plastic quality. This breakthrough not only reduces the environmental impact of plastic waste but also presents an opportunity for more efficient, sustainable recycling by preserving and enhancing the material’s value. By expanding this approach to a broader range of polymers and addressing the challenges of recycling thermoset plastics and improving solvent sustainability, the technology could significantly contribute to creating a circular economy for plastics.

Reference: Jeffrey C. Foster et al, Polyalkenamers as Drop-In Additives for Ring-Opening Metathesis Polymerization: A Promising Upcycling Paradigm, Journal of the American Chemical Society (2024). DOI: 10.1021/jacs.4c10588

Think this is important? Spread the knowledge! Share now.