Materials, from car tires to human tissues to spider webs, may appear vastly different, but they share an intriguing characteristic: they all rely on intricate networks of interconnected strands. These materials differ in composition, yet they all perform critical functions in various systems. What ties them together is the long-standing question surrounding their fracture durability. Specifically, scientists have sought to understand the energy required to fracture these networks—a crucial factor when designing materials for strength, resilience, and performance.

MIT researchers have recently cracked part of the puzzle with a study that introduces a new insight into the energy required to fracture materials with complex, networked structures. Their work, published in the journal Physical Review X, shines a light on a simple, universal law that governs the fracture energy across various materials, offering a fresh lens through which to view and enhance durability at both large and small scales.

A New Breakthrough in Fracture Mechanics

The research team, led by Xuanhe Zhao, a mechanical engineering and civil and environmental engineering professor at MIT, discovered a new rule—an overarching principle—that explains how materials made up of connected networks break apart under stress. These networks could be composed of many things, including the fibers in tires, the collagen networks in human skin, or the silken threads spun by spiders.

“Our findings reveal a simple, general law that governs the fracture energy of networks across various materials and length scales,” said Zhao. “This discovery has significant implications for the design of new materials, structures, and metamaterials, allowing for the creation of systems that are incredibly tough, soft, and stretchable.”

Until this research, no physical model could effectively link the mechanics of the individual strands (be they rubber, collagen, or silk) with their collective ability to withstand a fracture. The complexity of the connections, the density of the strands, and the material properties each played a unique role in fracture but had never been connected into a single theory. Now, thanks to MIT’s work, there’s an established universal scaling law that makes it possible to understand and predict how materials will behave under the stress of breaking.

The Core of the Discovery: Scaling Law for Fracture Energy

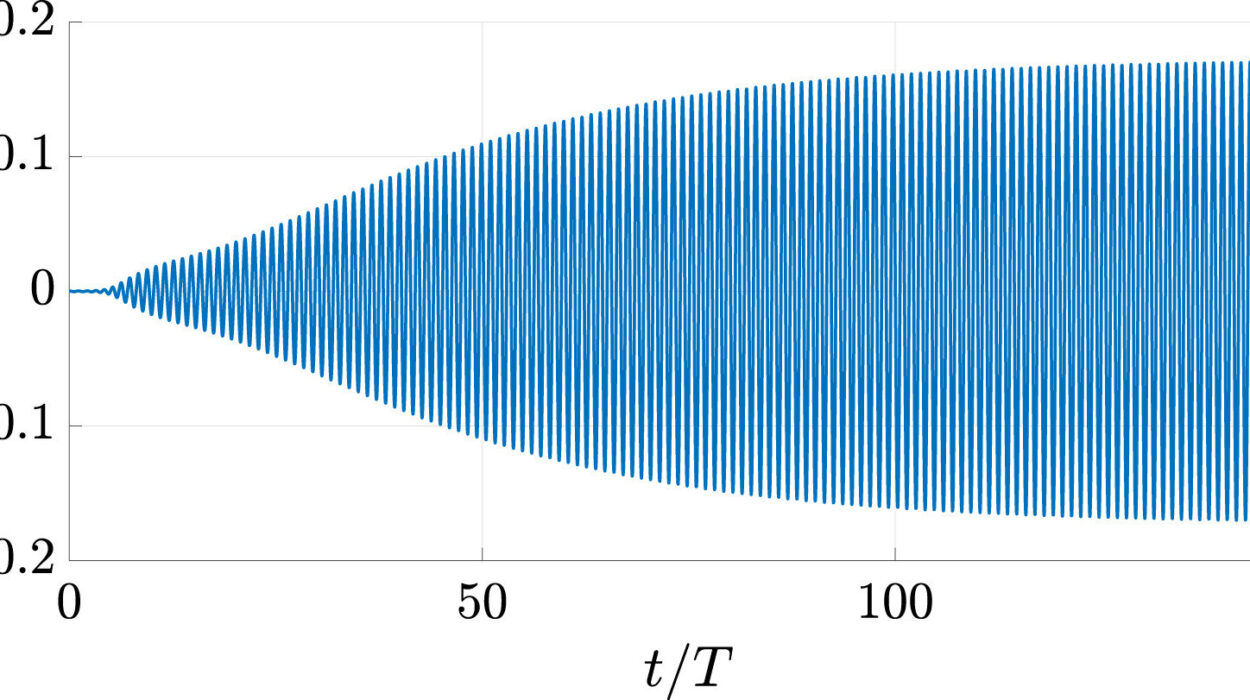

The innovation comes in the form of a scaling law—a formula that is capable of bridging different scales of materials, from the microscopic to the macroscopic. This law gives insights into how we can predict the intrinsic fracture energy of materials without needing a detailed, specific model for each new material. Whether the material at hand is a rubber network, biological tissue, or synthetic spider silk, this law applies universally.

Graduate student Chase Hartquist, one of the lead authors of the paper, emphasized the impact of the research: “This theory helps us predict how much energy it takes to break these networks by advancing a crack,” he said. Essentially, the new theory makes it possible for engineers to calculate, with great accuracy, how strong a given material is based on its constituent strands. The approach moves away from complex calculations for each material and instead introduces an easy-to-apply general framework.

But this knowledge offers more than just an academic insight. It directly affects the design of new, more durable materials. By understanding this energy relationship, manufacturers and researchers can design materials with improved toughness, allowing for the development of more durable and effective products—whether for medical use, consumer goods, or engineering applications.

Practical Application: 3D-Printing the Future

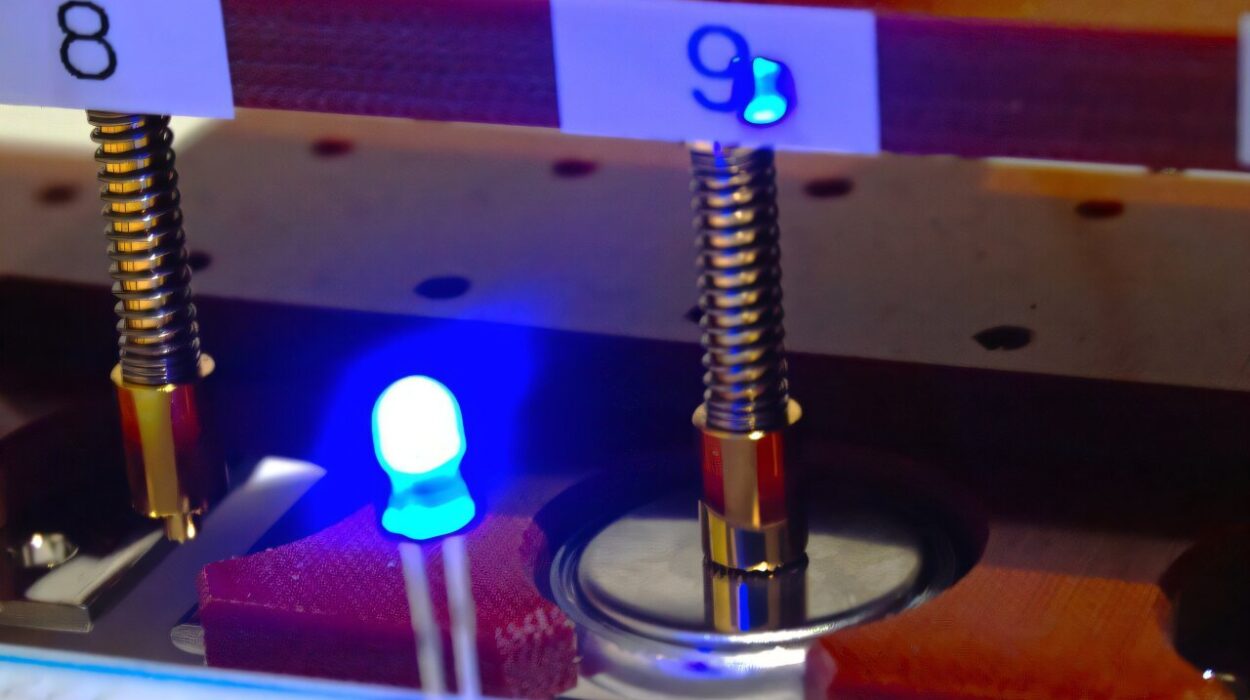

One of the ways the MIT team validated their theoretical insights was through 3D printing. By building an enormous, stretchable network as a prototype, they were able to physically test the properties of the material in the real world, showcasing their findings. The team created a model material with networks designed to stretch, bend, and undergo fracture testing. The results were compelling—despite the various physical and chemical differences between the materials tested, they all adhered to the universal rule.

This realization further proved that by adjusting the architecture of the networks—whether by making individual strands longer, more stretchable, or more resistant to breaking forces—we can alter and enhance the material’s durability. This adaptability provides the foundation for designing a wide variety of materials for diverse purposes, offering enhanced versatility, particularly in soft materials.

Broad Implications Across Multiple Domains

The benefits of this work reach far beyond the theoretical. Practical applications of the discovery are almost limitless. Car tires, for example, could be designed with enhanced fracture resistance, lasting longer even under severe wear and tear. The field of medicine could see major advancements in tissue engineering, with biological tissues designed to better resist injury or tearing, ultimately improving healing processes or reducing injury during everyday movements.

“By adjusting these properties, car tires could last longer, tissues could better resist injury, and spider webs could become more durable,” said Chase Hartquist. More durable tissues, for example, could better withstand stretching and bending, improving the longevity and safety of implantable devices or tissue replacements.

Spider webs could be optimized for even greater resilience, retaining the natural flexibility and lightweight characteristics that make them useful in a variety of applications, from crafting light materials to using webs in biological research. In fact, spider silk has long been a topic of intense scientific fascination, as it naturally balances durability and lightness.

In the broader context of material engineering, the theory and insights from this paper provide the backbone for the creation of metamaterials—materials designed with structures at the nanoscale that give rise to unusual mechanical, optical, or electrical properties. Designers of these architected materials can now apply this knowledge of network fracture to more effectively optimize their properties and improve the toughness and durability of these engineered products.

The Promise for Soft Robotics and Aerospace

The new findings are also set to impact fields such as soft robotics and aerospace technology. Soft robotic actuators, which use flexible and deformable materials to produce movement, could be designed to withstand a greater degree of stress and deformation without failing. These actuators, which play an important role in medical devices, prosthetics, and flexible machinery, can benefit significantly from the more durable materials identified in this study.

Similarly, aerospace technology can take advantage of the design improvements facilitated by this universal rule. When building lattices or structures used in lightweight yet high-performance aerospace materials, the insights into fracture resistance become critical for ensuring the safety and longevity of the components.

MIT’s work is contributing to the nascent field of architected materials, where the focus is on designing the material structure itself to give rise to specific, desirable properties. As this field advances, it could significantly enhance the performance and life span of engineered systems across numerous industries. The breakthrough offers a clearer path toward the design of future materials that exhibit the best characteristics of strength, elasticity, and resistance to fracture.

A Groundbreaking, Universal Strategy

Shu Wang, a postdoc in Zhao’s lab and a fellow lead author of the study, reflected on the discovery as an “extremely fulfilling moment” in their research. According to Wang, the universal scaling law makes it easier to design materials tailored to specific challenges: “It meant that the same rules could be applied to describe a wide variety of materials, making it easier to design the best material for a given situation.”

For the researchers at MIT, the significance of the work lies not only in how it sheds new light on the fracture behavior of materials but also in how it enables innovative designs for materials and systems in the future. From soft robotic actuators to biological tissues and aerospace materials, this groundbreaking work brings us closer to a world where we can design the toughest and most resilient materials with ease.

Conclusion

In conclusion, the recent breakthrough by MIT researchers has introduced a universal scaling law that governs the fracture energy of materials with interconnected networks. This groundbreaking discovery provides a simple, predictive framework that can be applied across diverse fields—from soft robotics to aerospace to tissue engineering—helping scientists and engineers design more durable, stretchable, and resistant materials. By focusing on strand length, stretchability, and force resistance, materials can be tailored for improved performance, leading to longer-lasting products like tires, stronger tissues, and more resilient spider webs. The work also paves the way for advancements in architected materials, where the structure within the material itself drives exceptional properties. This discovery not only advances our understanding of fracture mechanics but also sets the stage for innovative designs that can enhance safety, sustainability, and functionality in a broad array of industries. The potential applications of this research are vast, revolutionizing material science in the years to come.

Reference: Chase Hartquist et al, Scaling Law for Intrinsic Fracture Energy of Diverse Stretchable Networks, Physical Review X (2025). DOI: 10.1103/PhysRevX.15.011002