Half-metals are a fascinating class of materials that exhibit unique magnetic properties, making them highly sought after for developing next-generation technologies, particularly in mass-storage and spintronics. These materials are characterized by a half-metallic electronic structure, which means that one spin direction (up or down) has conducting electrons, while the opposite spin direction has insulating behavior. This distinctive feature makes half-metals a promising candidate for a wide range of applications, such as high-capacity data storage, magnetic sensors, and spin-based electronics.

A family of materials known as Heusler alloys is known to show potential for this half-metallic nature. These alloys are binary or ternary compounds typically consisting of transition metals like cobalt, manganese, and others. However, their half-metallic behavior can vary significantly depending on the composition ratio of the elements and the atomic ordered structure of the material. This variability can be challenging for materials researchers trying to optimize these materials for practical applications.

The Role of Spin Polarization

A key property tied to a material’s half-metallic behavior is spin polarization, a measure of how well the electron spins are aligned in one direction. Specifically, it refers to the difference in the number of electrons with spin pointing in the “up” direction versus those pointing in the “down” direction. For materials to exhibit half-metallic properties, the spin polarization needs to be high—that is, most of the electrons should either have spins aligned up or down.

In terms of practical application, spin-polarized current plays a major role in spintronics, where both the charge and spin of electrons are utilized to store and process information. For optimal performance in these technologies, it’s essential to optimize the spin polarization of the materials. Since the composition of the Heusler alloys directly influences this property, it’s important to determine and tune their atomic composition to achieve the desired spin polarization.

However, the process of accurately determining and measuring the spin polarization ratio has historically been a complex and time-consuming task. Current techniques often either rely on indirect measurements or require time-intensive steps that can slow down material optimization, which is a significant bottleneck in material science.

Breakthrough Method for Fast Spin Polarization Determination

Recognizing this challenge, a research team led by Professor Yuya Sakuraba of the National Institute for Materials Science (NIMS) in Tsukuba, Japan, sought to develop a faster, more efficient method for measuring spin polarization in Heusler alloys. Their work, published in the prestigious Science and Technology of Advanced Materials journal, leverages high-brilliance synchrotron radiation—a technique that uses intense beams of light to probe materials at the atomic level.

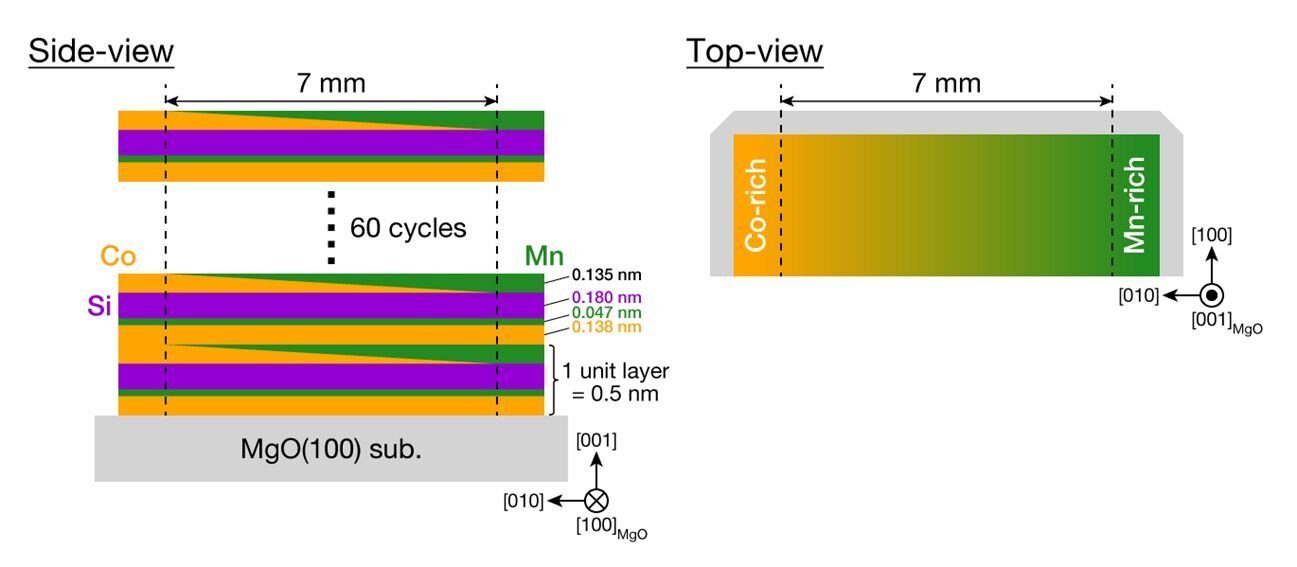

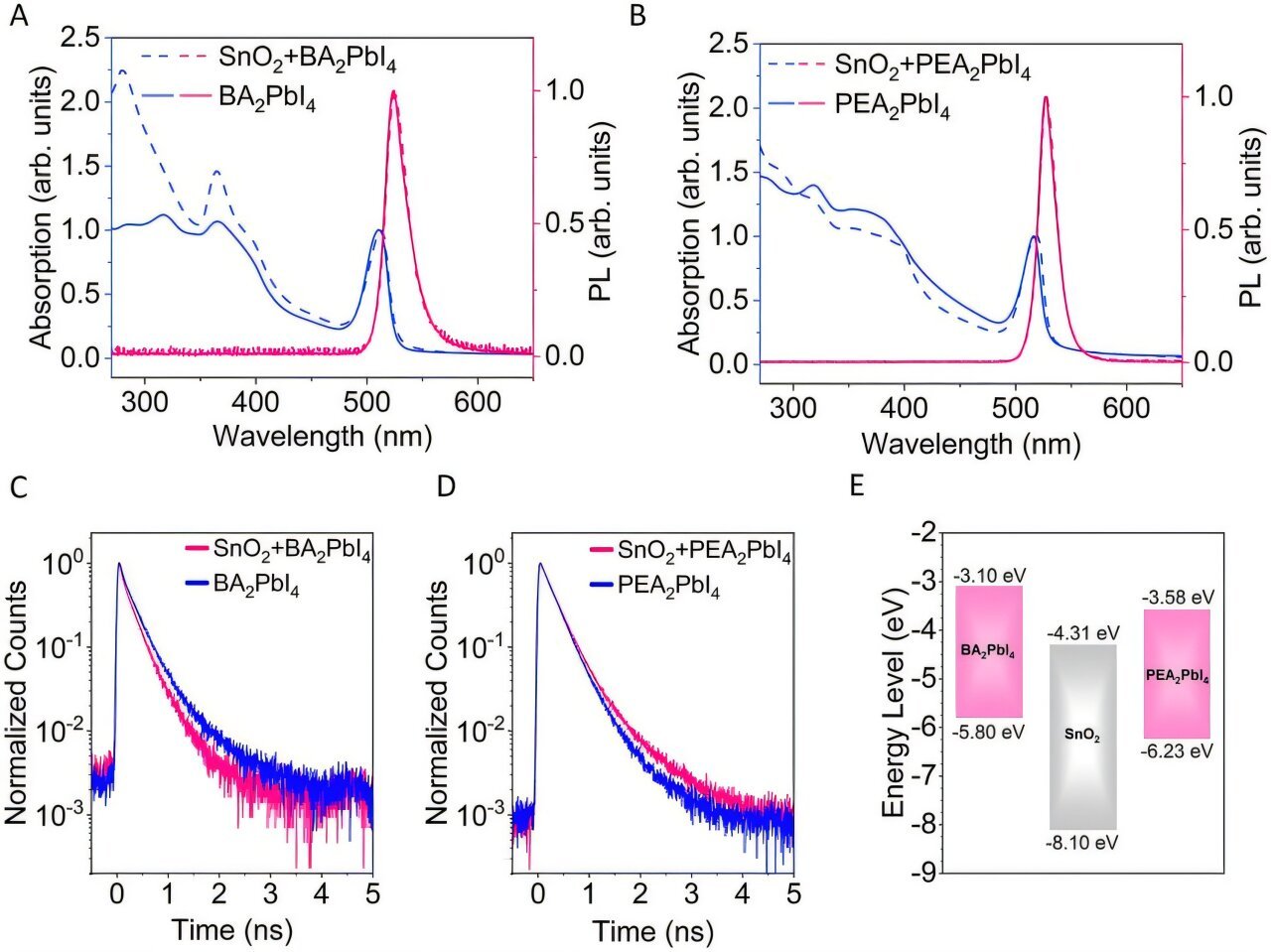

The approach adopted by Sakuraba’s team was revolutionary for its ability to quickly identify the ideal elemental composition that maximizes spin polarization in a specific alloy. To demonstrate their method, the researchers focused on a particular Heusler alloy composed of cobalt (Co), manganese (Mn), and silicon (Si). These elements were carefully chosen because they have shown promising half-metallic properties. The research team prepared composition-spread thin films of this alloy, where they varied the amount of manganese (Mn) within the film. The amount of manganese was adjusted from 10% to 40% across the sample, which created a composition gradient that enabled a detailed examination of how different ratios affected the spin polarization.

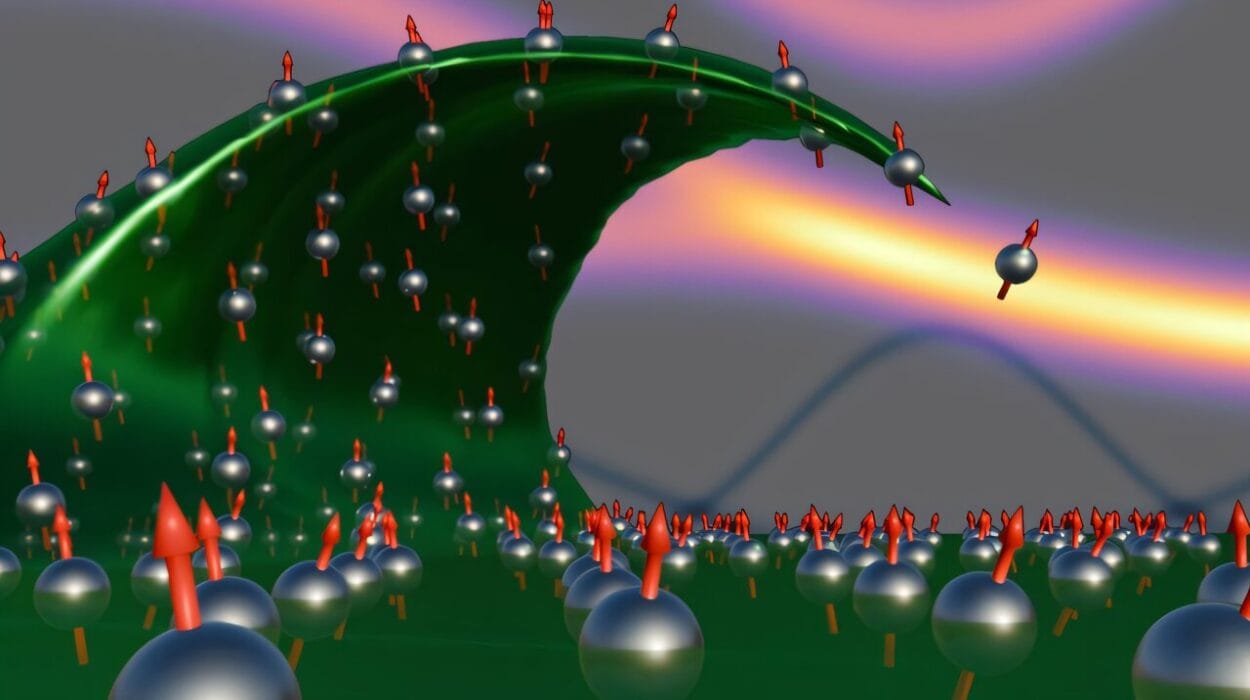

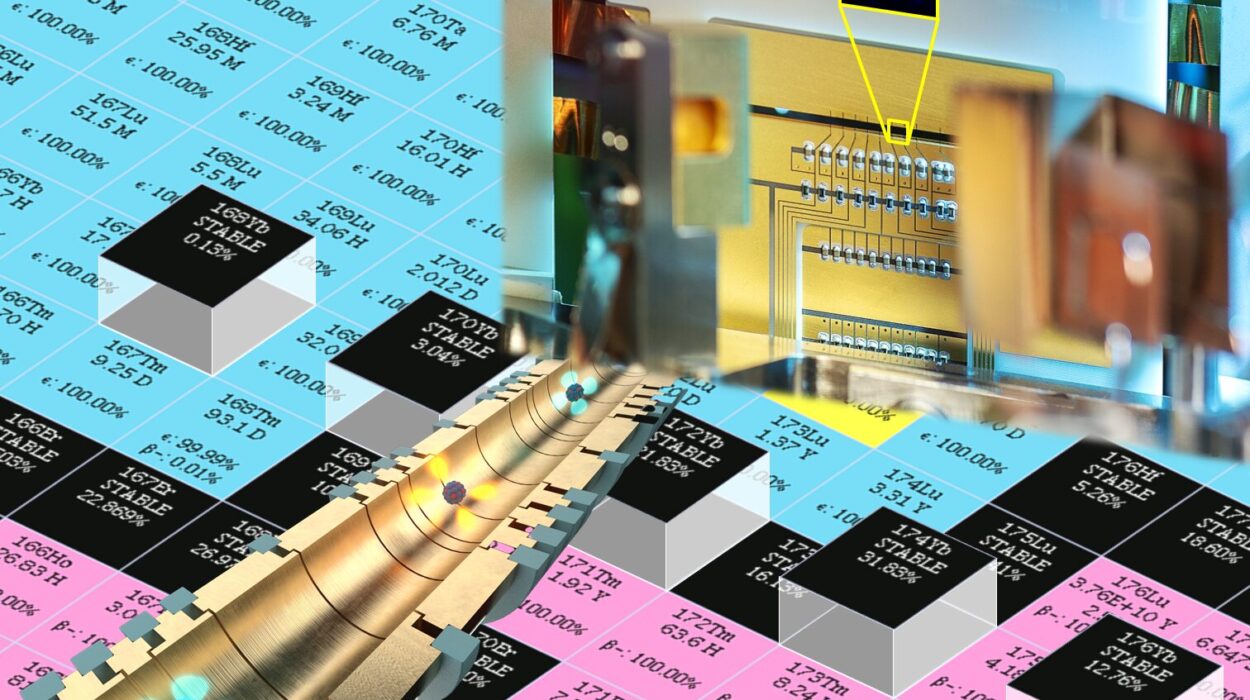

Once the thin films were prepared, the team exposed the samples to synchrotron radiation at the new NanoTerasu synchrotron facility, a state-of-the-art research center that had opened in April 2024. This facility offers high-brilliance radiation, allowing researchers to probe materials with unprecedented precision. By using photoelectron spectroscopy—an analytical method that helps scientists observe the electronic structure of materials—the team was able to measure spin polarization in the alloy in just a single day.

Identifying the Optimal Spin Polarization

The synchrotron radiation experiment at NanoTerasu proved a breakthrough in terms of speed and efficiency. In particular, the team discovered that the optimal spin polarization occurred when the composition of manganese in the alloy was 27%. This key finding marked a turning point in the development of Heusler alloys for applications requiring high spin polarization, offering a more effective and streamlined pathway for material optimization.

What made this method particularly impactful is that the experiment could be completed much faster than traditional methods, which would typically require several days or even weeks of data collection and analysis. Moreover, this technique provides a direct and clear measure of spin polarization, unlike other indirect techniques used previously.

Professor Sakuraba expressed his excitement about the advancement, highlighting the potential of their work: “The findings address a critical challenge in materials science by drastically reducing the time required to evaluate and optimize spin polarization in half-metallic materials,” he said. This breakthrough means that researchers can now rapidly identify optimal compositions for a range of materials, significantly accelerating the development process for applications in data storage and spintronic devices.

Broader Applications in Technology

While this study specifically focused on Heusler alloys, the method of high-brilliance synchrotron radiation and photoelectron spectroscopy is broadly applicable to many other types of magnetic and spintronic materials. As a result, the technique developed by Professor Sakuraba’s team has the potential to revolutionize the way materials are investigated and optimized for high-performance electronics.

In particular, spintronics—the field that exploits electron spin as an additional degree of freedom for information storage and processing—has seen significant advances thanks to insights from materials like half-metals. The ability to quickly characterize and improve spin polarization opens up new avenues for the development of high-capacity hard disk drives, magnetic random-access memory (MRAM), and advanced spintronic devices that promise greater speed and data capacity.

Not only does the new method promise accelerated material discovery, but it also leads to the possibility of more reliable and efficient devices. Optimized spin-polarized materials could help minimize energy consumption and increase the stability and reliability of devices, which are crucial aspects for the performance of next-generation electronics.

Conclusion

This research represents a significant milestone in materials science, addressing key challenges in the development of high-performance spintronic materials. The team, led by Professor Sakuraba, has demonstrated that using synchrotron radiation in combination with photoelectron spectroscopy can offer a highly efficient and rapid approach to characterizing spin polarization in half-metallic materials.

The ability to directly measure and optimize the spin polarization of Heusler alloys in a matter of hours, rather than weeks, accelerates the development of not just half-metallic materials but potentially a wide range of other magnetic and spintronic materials. This could have a profound impact on the future of mass-storage technologies and the growing field of spintronics, opening new pathways for faster, more efficient, and higher-capacity data storage devices. With this exciting breakthrough, the future of advanced materials science looks brighter, paving the way for cutting-edge innovations in electronics and beyond.

Reference: Ryo Toyama et al, High-throughput evaluation of half-metallicity of Co2MnSi Heusler alloys using composition-spread films and spin-integrated hard X-ray photoelectron spectroscopy, Science and Technology of Advanced Materials (2025). DOI: 10.1080/14686996.2024.2439781